There is a saying that food comes first for people, and the same goes for pets. Pet safety is the first cornerstone of every pet parent, and safe eating is responsible for the life and health of furry children. As a ten-year-old pet brand, Rose insists on independent research and development and production in its own factory. Starting from material selection, technology, nutritional value and even meeting specific functional requirements and particle shape, it truly returns to the real nutritional needs of pets themselves, and strives for excellence in every setting. , showing the greatest sincerity to users.

Integrity-based and quality-based, we are serious!

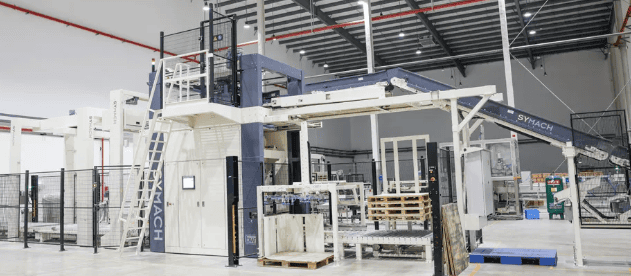

Owned S-level factory

Source Guarantee

Mese METZ Nantong Smart Factory is located in the Economic and Technological Development Zone of Nantong City, Jiangsu Province. It was completed and put into operation in 2019. The project investment is 500 million yuan and the factory covers an area of 50 acres. The factory has introduced the world's top equipment such as EXTRU-TECH extrusion unit and Swiss Bühler fully automatic production solution, with an annual production scale of up to 80,000 tons.

It is also one of the few domestic pet food factories with multiple international certifications!

We have our own S-class factory, produce independently, ensure product quality and safety from the source, and be responsible for the health of pet food , responsible for every ration of furry children.

Imported equipment

Safety and intelligence

Mese has worked intensively in the past 10 years, constantly optimizing production equipment and scientific research strength. At present, the import rate of factory equipment reaches 85%, and the import rate of core equipment is 100%, achieving safe, intelligent and efficient production, ensuring the high quality of every pet food.

Adhere to quality, not just 315, but also 365 days).

Core process

Leading technology

Mese is one of the first domestic pet food manufacturers to use the fresh meat grouting process.

Different from most domestic pet foods that use a large amount of meat powder, the Extru Tech 10T expansion unit expansion technology is the first technical solution proposed and applied in the field of fresh meat addition. It not only fundamentally solves the problem of wet materials Problems such as difficulty in processing and unstable products.

The mixing performance of materials has also been improved through software optimization system control, product quality has been improved, and the amount of fresh meat added has been increased to 70%.

Fresh meat injection is fresh ingredients+ Combining advanced technology, Meisi uses fresh meat grouting to allow pet food to retain more of the nutrition and flavor of fresh meat, greatly improving the quality of pet food.

Raw material supply

Consistent quality

We use high-quality, stable and sustainable raw material supply, and the quality has been consistent for 10 years.

High-quality care comes from the original intention. Rose adopts scientific formulas and is unambiguous in the use of raw materials, just to ensure that every ration of furry children is safe, healthy and reliable.

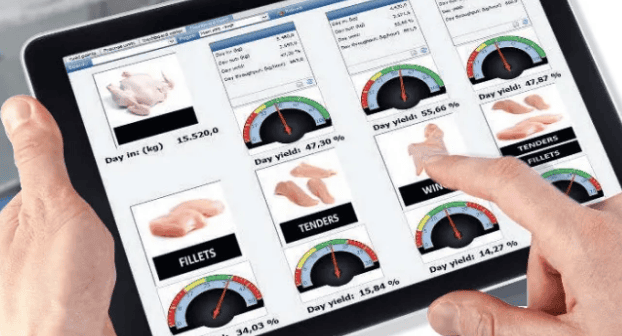

Safety testing

Full-link control of production quality

In order to maintain stable product quality, MESS insists on strict testing in every link of production, and every batch of products They are all sent to authoritative quality inspection agencies for testing, conveying trust in quality and making every parent feel at ease.

Pre-production

117 tests on raw materials: The raw materials must complete inspection and quarantine certificates, material transportation equipment testing, food freshness indicators (volatile base nitrogen ≤ 15mg/100g) and a series of nutritional indicators.

Mid-production

Mid-production sampling (30min/time): Semi-finished products are extracted in real time for eight routine tests (crude protein, crude fat, crude fiber, calcium, total phosphorus, water-soluble chloride, ash), and the DA7250™ near-infrared analyzer (only It takes 6 seconds to complete the detection of physical and chemical indicators (infrared)), TVT6700 food physical property tester, METTLER TOLEDO HE53 rapid moisture measurement instrument.

Post-production

Internal testing: The quality inspection center’s finished product sampling and internal inspection of retained samples can meet more than 30 testing contents of export certification standards, and control product quality in real time.

External testing: Depending on the different requirements of the product, the finished product will also be sent to authoritative third-party testing agencies to complete testing projects including American AAFCO, European FEDIAF, heavy metals, toxins, etc.

Meisi always adheres to the brand concept of "good feeding, visible", and creates good conditions for fur babies from good factories, good quality, and good raw materials.

In the future, Meisi will also write more ingenious answers in the pet brand, adhering to love and embracing the original intention, entering the hearts of thousands of parents, caring for and caring for the healthy growth of every furry child.

扫一扫微信交流

扫一扫微信交流

发布评论